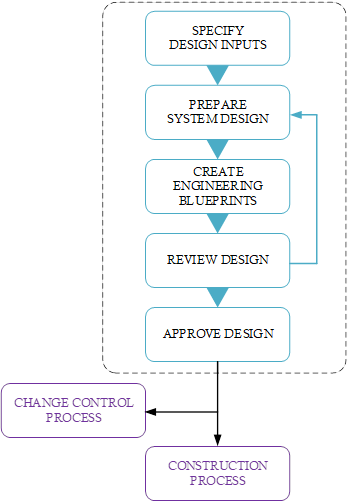

Quality and Performance in commercial and industrial scale solar PV projects can be achieved through properly established processes for Design, Procurement, Construction, Commissioning and Operation. This article provides insights on how to ensure quality in the solar systems at the design stage of the project. This process facilitates the designers to achieve the desired level of quality by following specific design-related inputs while designing ground-mount and rooftop C&I solar PV systems. It is a visible assurance that the inputs affecting the quality have been identified and planned for incorporating into the system design. A graphical illustration of the Design Process is shown in Figure 1.

Figure 1: Design Process for Commercial and Industrial Scale Solar PV Projects

Design Process relies heavily on the experience and competence of the system designer. Therefore, the process starts from the selection of a well-experienced individual or team.

(1). Design Inputs establish the criteria for the system design. They define the parameters and requirements upon which the detailed design is created. The inputs cover diverse requirements of the project. Most of the design inputs are acquired from the project site through a detailed survey. Generally, the documented requirements which the designers must follow include:

- site conditions e.g. roof orientation, pitch, available space, constraints, and shading structures

- roof type, structural strength, mechanical requirements for racking to support the dead load of panels and live loads of wind and snow

- sanction load, energy consumption, peak load, load profile, and energy consumption patterns

- codes, standards and jurisdictional requirements

- electrical requirements e.g. size and location of existing electrical panels for integration of the new solar system

- preference for PV modules, inverters and mounting structure to be selected

- layout, arrangement and accessibility requirements

- utility interface requirements

- battery storage requirements for Demand Charge Reduction or self-maximization of the PV-generated energy

- remote monitoring and performance requirements

- O&M requirements

- financial constraints

- Enterprises apply past experience for continually improving their solar designs, including lessons learned reports, operational data, performance monitoring, significant events, warranty claims, abnormal maintenance, and overall owners’ feedback.

(2). The designer produces a reliable, optimal, safe, efficient, and code-compliant system design. The most widely used codes and standards include:

- NEC 2023 or an earlier version for solar and electrical designs in USA

- IEC 62548 or IEC 60364-7-12 for solar photovoltaic systems and IEC 60-364-5-52 for electrical wiring in Europe and some other countries

- AS/NZS 5033 for PV Arrays and AS/NZS 3000 for electrical installations in Australia and New Zealand.

The designer selects the technology components, creates system architecture, and uses some industry-proven software for energy modeling, design optimization and performance assessment. After several rounds of iterative runs, fine-tuning and parametric simulations, the design is verified and finalized.

(3). Engineering Blueprints, the Design Output

During the design process, a great deal of documentation is produced including site plans, electrical diagrams, mechanical drawings, plan sets, equipment layouts, BOM, design descriptions, specifications, and general notes or instructions for the contractors and installers. Initially, these documents are used for permits and licenses from different governing departments, and subsequently for construction, operation and lifetime maintenance of the system.

(4). Independent Design Review by a single subject-area expert or team

Objective of the independent review is to provide assurance that the design fully meets the above mentioned requirements. The design is practical, efficient and cost-effective. The review identifies flaws and weaknesses well before it becomes too costly to correct them. The reviewer may use alternate tools and calculations to verify the accuracy and energy performance of the design. Design reviews are documented and records are maintained.

(5). The design is properly approved at appropriate level of authority.

(6). The detailed blueprints are issued for construction.

(7). Design Change Control The approved design is controlled. It comes under the umbrella of “Change Control Process.” Design changes may occur during field installation or commissioning. The reasons for changes may be design improvements or problems discovered during construction or testing. For any change request, the impact is analyzed, approved if valid, documented and records are maintained. Traceability of changes is necessary to maintain.